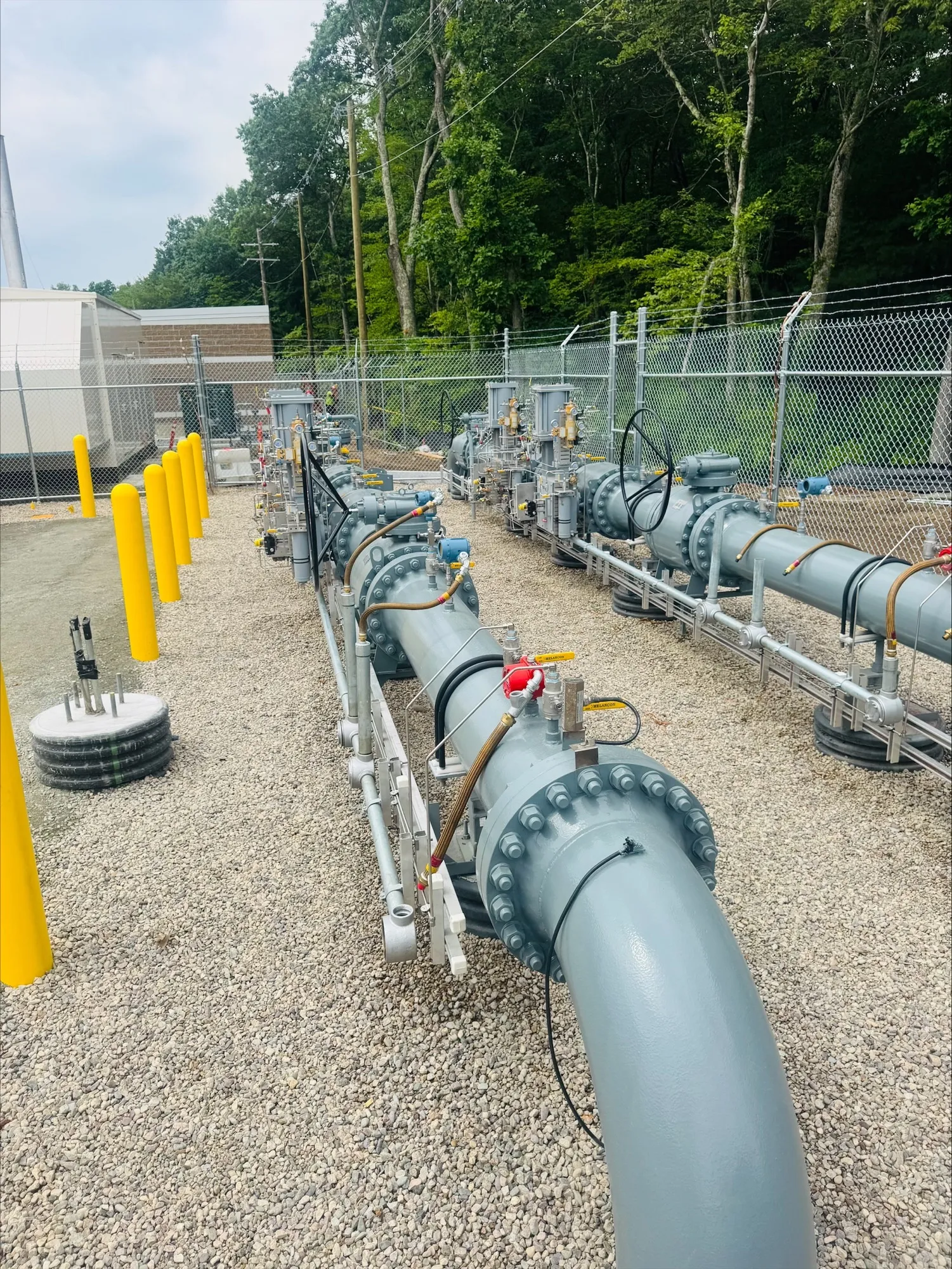

Eversource Overpressure Protection Station

Located in Easton, MA

- Company NEUCO

- Capabilities

- Distributed Power & Data Centers

- Natural Gas Infrastructure

- Completion 2025

Project Overview

In 2025, we completed our first Overpressure Protection (OPP) Station project for a utility customer at an LNG Plant in Easton, MA, marking a significant milestone in our work to strengthen energy infrastructure and protect the communities we serve. This complex project required expert coordination and strict safety measures.

Project Overview

In 2025, we completed our first Overpressure Protection (OPP) Station project for a utility customer at an LNG Plant in Easton, MA, marking a significant milestone in our work to strengthen energy infrastructure and protect the communities we serve. This complex project required expert coordination and strict safety measures.