Replacement and Installation Work

Located in Multiple States

- Company NPL Construction

- Capabilities

- Natural Gas Infrastructure

- Underground Infrastructure

- Completion 2016

Project Overview

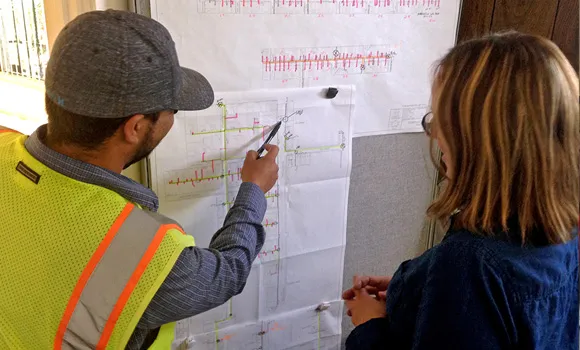

Infrastructure replacement and expansion play a big role in keeping energy reliable and sustainable for communities throughout the country. From 2011 through 2016, we were called upon to install and replace 500 miles of ALDYL-A pipe in southern Arizona for the largest natural gas distributor in the Southwest.

Key Highlights

Completed in six years, we replaced 2M feet of main pipe and over 500,000 feet of service pipeline. Throughout the project, teams drew on their construction and coordination capabilities to refine and synchronize processes, predict and resolve potential conflicts, and successfully mobilize and execute to meet the project goals, resulting in zero major safety incidents or environmental incidents.

Project Overview

Infrastructure replacement and expansion play a big role in keeping energy reliable and sustainable for communities throughout the country. From 2011 through 2016, we were called upon to install and replace 500 miles of ALDYL-A pipe in southern Arizona for the largest natural gas distributor in the Southwest.

Key Highlights

Completed in six years, we replaced 2M feet of main pipe and over 500,000 feet of service pipeline. Throughout the project, teams drew on their construction and coordination capabilities to refine and synchronize processes, predict and resolve potential conflicts, and successfully mobilize and execute to meet the project goals, resulting in zero major safety incidents or environmental incidents.